You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A

ad fez

Guest

Nice tip on the rise guys. ... I'll havea look bit I don't think mine has a loop or a Rise.... great job

M

Madbrush

Guest

Well I'm done. .... and I hate my own voice https://www.youtube.com/watch?v=z_LVU6vZ4v4&feature=youtube_gdata_player

Thanks for the whole thread Fez, I have been following the thread but not saying much because I'm too stupid, or at least I thought I was until I checked out the video, I've wanted to do this for sometime but other build SBS's seemed to confuse me, this thread and the video have shown me just how simple it can be and will be a handy reference when I eventually get to start.

I do have a couple of questions or rather points that need verification, due to limited space I have a small 6 liter cylindrical type tank similar to a gas bottle without the stand, but having seen this I think one very small fridge compressor from a mini fridge or under the bar drinks cooler would be sufficient, would that be correct, and also, the wiring process I would assume would be somewhat simpler?

I'ts very unlikely I shall ever require more pressure than 50 - 60 PSI, I generally work between 5 - 10 PSI with seriously thin water based paints, I up the pressure occasionally to around 30 for speed filling of large areas, but other than that I don't need anything big or substantial, so I also assume that my regulator can be 6 - 8 bar maximum?.

I may hit you with some queries (if I may) at another time or Talla (bless him) in the meantime thanks again, the video is cool, the compressor looks and sounds sweet and there's nothing wrong with your voice at all,

A

ad fez

Guest

Hey mate. ... the 2 I have...I would say are mid size comps. .. you can get somea fair bit biggeri think these are from a standard fridge unit..I probably wouldn't go any smaller for your use but you would be fine with just 1 Fir sure. .... so long as you installa check valve directly after the comp pressure is only really governed by your tank so 8 bar is no prob at all

M

Madbrush

Guest

Hey mate. ... the 2 I have...I would say are mid size comps. .. you can get somea fair bit biggeri think these are from a standard fridge unit..I probably wouldn't go any smaller for your use but you would be fine with just 1 Fir sure. .... so long as you installa check valve directly after the comp pressure is only really governed by your tank so 8 bar is no prob at all

Thanks mate, my tank is about 40 cm long and about 20 cm in diameter, I intend to lie it on it's side with the comp above it with the intention of keeping the whole unit within the same dimensions, meaning 40 cm wide and 20 cm deep (front to back) the height isn't important but don't expect it to be higher than 50 or 60 cm, with these dimensions it will fit snugly under my worktable at either side so that I will rarely ever have to move it.

I've had a look around for the parts I don't yet have and can't believe how cheap they are, from what I've seen so far I can build mine for under 50 quid if I can get a donor or used fridge motor, the beauty of that is the size I need is easy to get free, I might even be able to find a donor compressor, I already have tubing to make the frame and my father in law has every kind of pipe bender you could think of, he used to be a ships diesel fitter before he retired and refuses to let go of his tools, lucky for me,

It will be a nice project for the winter and fun to do, your little walk around in the video is an absolute diamond and it shows everything very clearly, even a clueless idiot like me can understand it,

OH, And I found 2 regulators in my hobby room, one is 8 bar (just what I need) and the other is 12 bar, depending on the fridge motor I might just use that one, it came off the same compressor where the tank came from and I think I have some fittings that came from there too

I'll post a progress report when I start.

A

ad fez

Guest

If you want a clearer video of exactly how everything is connected then just let me know Bro.....I did havea bit of help with the wiring but at least I can take the cover off and show you what goes where

M

Madbrush

Guest

If you want a clearer video of exactly how everything is connected then just let me know Bro.....I did havea bit of help with the wiring but at least I can take the cover off and show you what goes where

Thanks again Fez, I think it should be OK, since there will only be one comp the wiring should be straightforward, I'm used to complicated wiring with my models and I think once I start I should be able to work it out, but I'm sure I saw an appropriate photo of the wiring process in one the links posted here or in another thread, but I still have to get the rest of the stuff I need, so please don't go stripping yours down just yet,

I was more concerned about the layout of all the components, but your walk around in the video shows all that very good, I don't think I can get a start until the new year, but I'll pop you a line whenever I get stuck,

airbrushingferret

Air-Valve Autobot!

I am ging to have to read this thread word for word i am thinking of ding this instead of buying a 500 dollar compressor when i get to Florida

airbrushingferret

Air-Valve Autobot!

I have gone through most of this thread and i am convinced its the way to go thanks fez and yes you do sound sophisticated

M

Madbrush

Guest

If you want a clearer video of exactly how everything is connected then just let me know Bro.....I did havea bit of help with the wiring but at least I can take the cover off and show you what goes where

OK Mr Fez, I finally managed to get hold of a fridge motor, I got it from one of my neighbors who just happens to be a hoarder (like myself), he had about four in his shed and let me choose one, and I got it for free, only problem is when he dismantled the original fridge, he just cut through all the wiring, I know it's capable of 12 bar, which is ideal because my 6 liter tank is safe up to 12 bar as is my regulator, I still have to find a pressure cut off switch, non return valve and air release valve but these cost almost nothing and are the only things i actually need to pay for.

I plan on painting both the fridge motor and tank a nice colour before I begin with the build, but it might take me a while to get the rest of the parts.

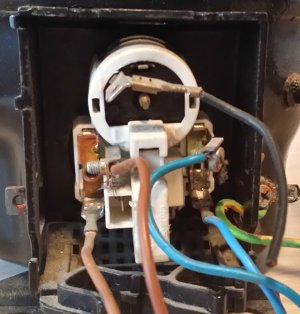

It seems Fez, I might need to take you up on your offer of photos of the wiring, you can see in the photos here the pipes on the motor it'self as well as what's left of the wiring of the electrics, If possible photos of the wiring at any one of your motors and also at the pressure cut off would be extremely handy, however, please don't take your compressor apart if you think it might be detrimental to your equipment.

I am in no hurry since I want to first prepare a frame and paint the parts as mentioned, so it will be a while before I get started with building, any way check out the photos and if you (or anyone else) can tell me what each of the pipes do and what the wiring should look like.

W

wmlepage

Guest

Did you make sure you got the starting capacitor that was attached to the compressor? If not it will never run. You guys being from across the pond operate on different voltage than us in the US. I think my compressor only had 3 wires. You may be able to just tie the like colored wires together.

Sent from my iPad using Tapatalk HD

Sent from my iPad using Tapatalk HD

W

wmlepage

Guest

From the pics I only see the motor contractor and wires. You may have to go back to your neighbor and grab a different compressor so you can have the starting capacitor.

Sent from my iPad using Tapatalk HD

Sent from my iPad using Tapatalk HD

A

ad fez

Guest

pipe wise the rusty crimped one is your oil intake.... i cut this back to just behind the collar and crimped some hose on to it with a bung in the end for easy filling, the pipe below that should be your air oulet, and the one on the left side of comp should be air intake.....

no probs on wiring diagrams ill sort that as soon as bro

no probs on wiring diagrams ill sort that as soon as bro

A

ad fez

Guest

true dat!!!From the pics I only see the motor contractor and wires. You may have to go back to your neighbor and grab a different compressor so you can have the starting capacitor.

Sent from my iPad using Tapatalk HD

M

Madbrush

Guest

From the pics I only see the motor contractor and wires. You may have to go back to your neighbor and grab a different compressor so you can have the starting capacitor.

Sent from my iPad using Tapatalk HD

Thanks WM, the neighbor tested the motor to see if it was running and it was, so I'm assuming that the white ring you see in the photo at the top with black wire attached is probably the start capacitor, I could be wrong, but I'll check that later and if it isn't the case I can more than likely get that part separately, even from the neighbor if need be.

When I look at the blue and brown cables they are both continuous circuits with no breaks, so I am assuming that one blue and one brown were used in conjunction with the black and a thermostat when the fridge got cool enough, this makes me think that only one of each with the black is enough to run the motor in conjunction with the pressure cut off.

England uses 240 volts and Holland or indeed Europe uses 230 volts, however the difference is minimal so the fridge motors operate between 220 - 250, this allows for the difference and for slight power surges, If I'm not mistaken America uses 110 volts?.

A

ad fez

Guest

lets all laugh at america with its inferior voltage.... MmmmwWWWAAAaaHHHhhhhhaaaaaHHH

M

Madbrush

Guest

UPDATE: I just checked around and the starter capacitors are readily available, now I'm assuming that's what was attached to the other brown and blue wires and possibly the black, they are not expensive and from what I understand are only there to cut the the motor in the event of an overload and can be bypassed since the pressure cut off will provide this function? since the neighbor was able to test the motor without it, I would think it's not needed, but a little extra protection is not a bad thing, certainly for the measly ten dollars it might cost.

SilverScreen

Gravity Guru

Normaly a capacitor are put in with a 3 fase motor if it must run on 2 fase like in 220 or 110 volt. But the fridge factories made a smart gadged, a relay that replace the capacitor and is not vorn out over time as a capacitor often are. I don't know the exact way it work, but it is among the wirering and where the capasitor just help to push a start, the relay add the full spark to replace a fase. With 3 fases there are no capacitor, it's just a mean to make small 3 fase motors start and run, if there are only 2 fase avaible. --- (Just me playing a smart guy.) But what this mean, are that if there are trouble starting a fridge compressor even a capacitir are there replacing the mains on one fase, it proberly are the capacitor that is vorn out, being leaking or dried out. --- Btw. never touch the two wires from the capacitor as it accumolate the 110 or 220 volts and will spark it even the plug are out..

SilverScreen

Gravity Guru

Just want to add, that there are much more efficient compressors, that those for small fridges. When I made our famous airbrush fridge compressor in 1968 I were carefull to saw the outher rim of of the two shells covering the compressor, so I opened the "container", both to see how it was made, but also to bring the intake away from the oil splashing. ( as before it was lubricated thru the fridge liquid, it processed to be a fridge compressor. I did so just attaching a rubber hose so you take the air from outside the compressor. Normaly there are no oil there, it's not nessery as the shell have aa second function in a fridge, Anyway, all electrics are just open inside, best to use a compressor oil --- still the one I got were atleast 3 times as efficient than a small fridge compressor, I measured it to 10 Atm. it was two cylindred and more capasity than a two cylindred dentist compressor, ---- offcaures I found a load in a scrapyard, and it was not the biggest I renovated.

Last edited:

A

ad fez

Guest

Feel like crying a little bit..... a few weeks ago I took my compressor to a chaps house to show him a few bits and on the way round there i went round a corner a little to quick and the compressor toppled over! All the oil came out of it, so I stripped it down of component parts and gave it a clean, built it back up and topped it with compressor oil.... bloody motor has just seized on me and oil has gone frothy, clearly the oil i used was not the right kind and I've just fornicated my compressor. More than likely I'm gonna have to wait till xmas till I can scrape it together to get a new one. fornicate my life