M

modeler

Guest

Hi All

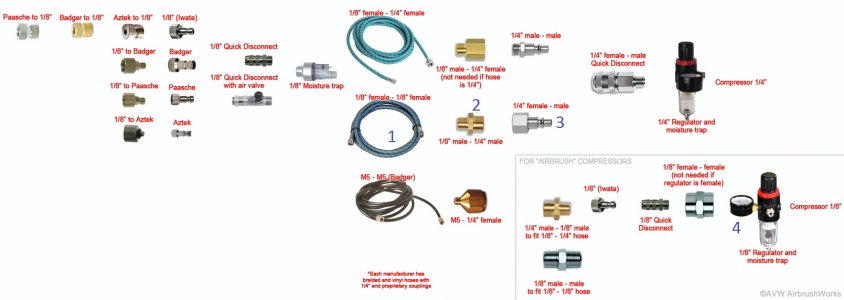

Quick question here, I have purchased a airbrush, with the M10 air inlet, but my compressor is airtool compressor with 1/2" outlet, so I need an airbrush pipe that can take 1/2" and output to M10. Or I will need a coupler, exact that convert btw metric 10 and 1/2" ?My compressor also come with a coiled pipe that have a output of 5/16" , so M10 - to 5/16" coupler should also works for me.

Please advise where I can see a comprehensive list of couplers

I know I can buy a 5/16" barbed fitting, and the airbrush come with a barbed fitting too, so I can find a piece of silicon tube and fits to the two sides, does it work? is the air pressure going to push the barbed fitting out of its pipe?

All the above thread size is accurately measured at hardware store, by matching the screw and bolt template, I hope air tool use same standard used in hardwares

Quick question here, I have purchased a airbrush, with the M10 air inlet, but my compressor is airtool compressor with 1/2" outlet, so I need an airbrush pipe that can take 1/2" and output to M10. Or I will need a coupler, exact that convert btw metric 10 and 1/2" ?My compressor also come with a coiled pipe that have a output of 5/16" , so M10 - to 5/16" coupler should also works for me.

Please advise where I can see a comprehensive list of couplers

I know I can buy a 5/16" barbed fitting, and the airbrush come with a barbed fitting too, so I can find a piece of silicon tube and fits to the two sides, does it work? is the air pressure going to push the barbed fitting out of its pipe?

All the above thread size is accurately measured at hardware store, by matching the screw and bolt template, I hope air tool use same standard used in hardwares

Last edited by a moderator: