crewchief227

Needle-chuck Ninja

Hello all,

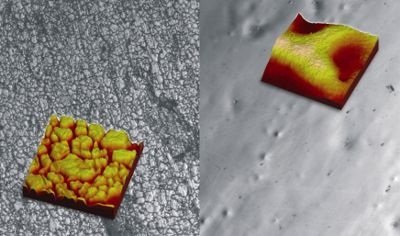

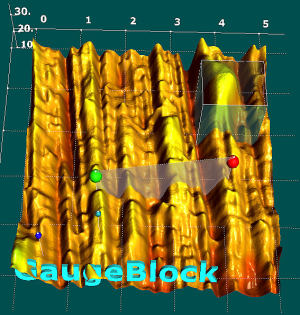

New to the forum and glad to be here. This must be like the 10th wed forum I have joined. Anyways, I was practicing today and had a oh crap moment. I noticed the needle had a very slight bur on the tip, almost unable to see with the naked eye but could feel it with my fingernail. So I decided to take this opportunity to try something. I mean hell the needle was already bad what's the worse that could happen? So I do a full tear down of my HP-CS and bust out my diamond sharpening set for my knives. Needless to say after an hour or so of VERY careful sharpening and polishing I ended up with something amazing. A diamond polished needle that is better then an original. Not only do I have my fine detail back I also have less tip dry and picking less. Why can't Iwata do this? Also it had me wondering if you could actually make a needle from ceramic or say tungsten. Something ultra smooth, I know ppl will say that ceramic would be to fragile, but would it? I mean at that size anyway even steel is pretty fragile. Personally I vote for tungsten with a tip to match. Anyways that's my rant, there are some pics attached.

New to the forum and glad to be here. This must be like the 10th wed forum I have joined. Anyways, I was practicing today and had a oh crap moment. I noticed the needle had a very slight bur on the tip, almost unable to see with the naked eye but could feel it with my fingernail. So I decided to take this opportunity to try something. I mean hell the needle was already bad what's the worse that could happen? So I do a full tear down of my HP-CS and bust out my diamond sharpening set for my knives. Needless to say after an hour or so of VERY careful sharpening and polishing I ended up with something amazing. A diamond polished needle that is better then an original. Not only do I have my fine detail back I also have less tip dry and picking less. Why can't Iwata do this? Also it had me wondering if you could actually make a needle from ceramic or say tungsten. Something ultra smooth, I know ppl will say that ceramic would be to fragile, but would it? I mean at that size anyway even steel is pretty fragile. Personally I vote for tungsten with a tip to match. Anyways that's my rant, there are some pics attached.

Attachments

-

2014-09-10 12.59.46.jpg138.6 KB · Views: 58

2014-09-10 12.59.46.jpg138.6 KB · Views: 58 -

2014-09-10 13.05.44.jpg827 KB · Views: 55

2014-09-10 13.05.44.jpg827 KB · Views: 55 -

2014-09-10 13.11.42.jpg79.8 KB · Views: 55

2014-09-10 13.11.42.jpg79.8 KB · Views: 55 -

2014-09-10 13.12.29.jpg186.9 KB · Views: 54

2014-09-10 13.12.29.jpg186.9 KB · Views: 54 -

2014-09-10 13.14.14.jpg165 KB · Views: 54

2014-09-10 13.14.14.jpg165 KB · Views: 54 -

2014-09-10 13.25.53.jpg129.1 KB · Views: 54

2014-09-10 13.25.53.jpg129.1 KB · Views: 54 -

2014-09-10 13.29.10.jpg133.7 KB · Views: 53

2014-09-10 13.29.10.jpg133.7 KB · Views: 53 -

2014-09-10 13.35.04.jpg169.8 KB · Views: 49

2014-09-10 13.35.04.jpg169.8 KB · Views: 49