You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Masters 2 piston compressor help please

- Thread starter Rob Afton

- Start date

I wonder if this is the right video for your situation...Looks like you are pointing to pressure switch. But to be honest I don't have a clue.

Don't listen to me, something could blow up -.-

Don't listen to me, something could blow up -.-

Last edited:

Rob Afton

Young Tutorling

Well according to the compressor manual he part it’s leaking air from is called the piston solenoid since it’s a 2 piston compressor this part is on the one piston then it sends air to other piston and then they both go to the tank,. I am gonna call tcp tommorw and see if they can help, on Amazon many people have them arrive with this problem. I wonder if there was a lug at some point and it fell out thank you for the Responses

Posting this videos cause it's interesting subject. If you have warranty? you should be good.

Maintenance and Operation of a Pilot Piston Solenoid Valve

Maintenance and Operation of Direct Lift Piston Solenoid Valve

Maintenance and Operation of a Pilot Piston Solenoid Valve

Maintenance and Operation of Direct Lift Piston Solenoid Valve

jord001

Air-Valve Autobot!

A bit of info on the Masters 2 piston compressor TC828

Double Switch for Automatic On/Off Shutoff:

Could this be what is happening to yours? Which is normal and not a problem.

Lee

Double Switch for Automatic On/Off Shutoff:

- First Switch Position: Preset for automatic turn on when air tank pressure is below 43 PSI and Preset for automatic turn off when air tank reaches 57 PSI. The reduced running time means there will less motor wear and less heat-related moisture enabling a longer compressor life.

- Second Switch Position: Allows air tank to reach the maximum pressure of 85 PSI then the Automatic Safety Release Valve releases the excess pressure.

Could this be what is happening to yours? Which is normal and not a problem.

Lee

Last edited:

Rob Afton

Young Tutorling

Yes it always relived the excess from this part however it never stops I took the whole thing apart and checked it’s an electric solenoid, unfortunately the ware thank you is Up worst part is I never even used this compressor it was my spare and I only tested it upon receiving. I am gonna have to buy a new one, now it’s decided it don’t want to kick on I take it I got a lemonA bit of info on the Masters 2 piston compressor TC828

Double Switch for Automatic On/Off Shutoff:

- First Switch Position: Preset for automatic turn on when air tank pressure is below 43 PSI and Preset for automatic turn off when air tank reaches 57 PSI. The reduced running time means there will less motor wear and less heat-related moisture enabling a longer compressor life.

- Second Switch Position: Allows air tank to reach the maximum pressure of 85 PSI then the Automatic Safety Release Valve releases the excess pressure.

Could this be what is happening to yours? Which is normal and not a problem.

Lee

jord001

Air-Valve Autobot!

Sorry I misread that it was constantly bleeding air. Could just be a dodgy part or theres some dirt stopping the valve from shutting off totally. If you can strip it have a go, take pics so you dont get it wrong putting it back together, it only needs a tiny bit of dirt to stop it closing. It may just fix it and if not i'm sure you can get replacement parts pretty cheap..

edit:

Not sure if this is the same, but its similar https://www.wiltec.de/airbrush-comp...sor-solenoid-valve-coil-as189-as196-as19.html

Looking at what compressor it fits = AS189 / AS196 / AS19

I checked out the AS196 and max pressure is 6 bar or about 85psi. So if it fits then it will work at the same pressure as the faulty one. Well worth giving it a go. I fixed my Iwata PowerJet Pro as it had a worn bearing, took my time and took lots of pics. There's not much to them inside.

Lee

edit:

Not sure if this is the same, but its similar https://www.wiltec.de/airbrush-comp...sor-solenoid-valve-coil-as189-as196-as19.html

Looking at what compressor it fits = AS189 / AS196 / AS19

I checked out the AS196 and max pressure is 6 bar or about 85psi. So if it fits then it will work at the same pressure as the faulty one. Well worth giving it a go. I fixed my Iwata PowerJet Pro as it had a worn bearing, took my time and took lots of pics. There's not much to them inside.

Lee

Vladimir

Detail Decepticon!

So all the sudden my compressor is slowly letting air out of this side of the twin pistons? How do I fix this ? Why is this doing that ?

What you describe is not a problem, I suppose. And there's nothing ti fix there.

I had similar compressor to yours (decade ago), it had the same valve. This valve works for letting air off the line between the pistons and the tank for the reason motor would start unloaded. The valve makes loud noise when switch regulator shuts the motor and then it makes very very silent "shhh" sound when the motor is off. I don't know if that silent sound is normal thing, but it's the way mine worked and I had no worries about it.

My big compressors make no silent (or other kind) sounds while shut off, but they have different valves compared to the one used in these type small compressors. So, there's no reason to compare them.

Last edited:

my compressor makes so much noise I almost needed a diaper first time hearing that sound...My big compressors make no silents (or other kind) sounds while shut off, but they have different valves to the one used in these type small compressors. So, there's no reason to compare them.

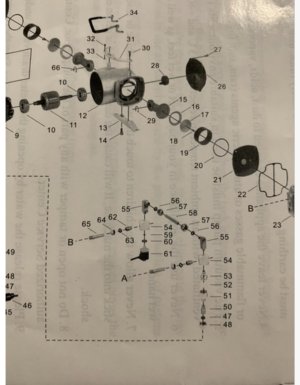

I rotated and embedded it for easier viewingI don’t know why it post the pic sideways how do I rotate it ? For some reason it show correctly when posting?

Rob Afton

Young Tutorling

Yes vlad, it always releases the air in the pistons when the compressor cuts off. However, before when I first got it, it would not drain the entireWhat you describe is not a problem, I suppose. And there's nothing ti fix there.

I had similar compressor to yours (decade ago), it had the same valve. This valve works for letting air off the line between the pistons and the tank for the reason motor would start unloaded. The valve makes loud noise when switch regulator shuts the motor and then it makes very very silent "shhh" sound when the motor is off. I don't know if that silent sound is normal thing, but it's the way mine worked and I had no worries about it.

My big compressors make no silent (or other kind) sounds while shut off, but they have different valves compared to the one used in these type small compressors. So, there's no reason to compare them.

1 gallon tank and cause the compressor to turn back on and run every min or so filling tank and then letting it out of the valve even when not using an air brush. If I set the double switch to 1 it fills up the tank and shuts off at 4bar then all air leaks out of the solenoid. So if I fill tank then turn switch off attach a hose with a brush on it wait 1 min then try and use the brush there is no air pressure. When I first got it it would store air in the tank. Not an big 8gal tank like my oiled compressor but still in the start it would fill the tank and shut off at 6 bar I could mix paint and start painting before it ever kicked on again now it fills bleeds all the air then fills again without me air brushing. It’s supposed to release the excess but not all. Basically the solenoid isn’t closing or a checks valve deeper on. Because now that I think of it maybe the solenoid is working after all Air doesn’t come out when it’s filling the tank, I feel this is because of the pressure going into the tank but once that pressure stops all the air leaks back out through the same way. I looked over the diagram and can’t see any part that would behave in this way

Similar threads

- Replies

- 8

- Views

- 269

- Replies

- 8

- Views

- 278