You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My RK-001 Head Cap is very tight!

- Thread starter Than

- Start date

Robbyrockett2

Air-Valve Autobot!

Mine had defective threads in one aircap as well.

after the first time using the pliers you should be able to undo it by hand, sometimes from the factory they can be overly tight.

if you have to do it up with pliers to get it working properly (no air leaks or bubbles around the threads if you dab some soapy water on it) then its not as it should be and you should contact Badger.

if you have to do it up with pliers to get it working properly (no air leaks or bubbles around the threads if you dab some soapy water on it) then its not as it should be and you should contact Badger.

DaveG

Airbush Analyst

Exactly like what JackEb said. I believe they use soft jaw pliers to assemble the brushes, and sometimes they can be a little aggressive. Once loosened, you shouldn't have much trouble - you may need to run it onto the threads few times to get a feel you like.

The one thing I would question about Jakie's post - Badger head pieces almost always leak air . I have never had one that sealed completely without using chapstick or wax. The air leak is not really an issue, though - just a personal peeve. They work fine without the need to seal the head pieces.

. I have never had one that sealed completely without using chapstick or wax. The air leak is not really an issue, though - just a personal peeve. They work fine without the need to seal the head pieces.

The one thing I would question about Jakie's post - Badger head pieces almost always leak air

The one thing I would question about Jackie's post - Badger head pieces almost always leak air. I have never had one that sealed completely without using chapstick or wax. The air leak is not really an issue, though - just a personal peeve. They work fine without the need to seal the head pieces.

Maybe that’s why I never got into Badger brushes

Than

Young Tutorling

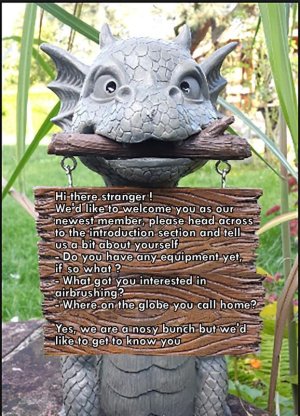

oknow you have an answer how about heading over to the Intro section and give us a little insight about yourself

View attachment 60092

DaveG

Airbush Analyst

The caps are not indexed to the hold down ring, so there is no telling what the orientation of the prongs will be when tightened down. I have a few that are near vertical, and many that are not. I usually use the cap with no prongs - but, you obviously need to take care not to bend the needle.This is an AB head which I can screw by my hand. If I rotate prongs to horizontal line. Air leak’ ll happen.

S

Sim

Guest

I received my Renegade Velocity Jet R4VJ last week from my local Amazon. The airbrush appeared as if it took part in the brutal Battle of Berlin 1945. Surface was old, tarnished and scratched (may be it suffered a few ricochets from an anti tank gun). Inside the cup was a black gum that took me some scrubbing to remove. Anything that was threaded was locked. Needed WD40 and a pair of pliers to loosen. And no, I still needed pliers to tighten it back. Finger strength didn’t move anything at all. Nozzle was jammed stuck too. WD40 again. After an hour of deep cleaning, it worked fine. Until today, even with tamiya blue cap grease or chapstick on all threads, I still need pliers to remove any part, making cleaning a chore.

Leakyvalve

Mac-Valve Maestro!

I received my Renegade Velocity Jet R4VJ last week from my local Amazon. The airbrush appeared as if it took part in the brutal Battle of Berlin 1945. Surface was old, tarnished and scratched (may be it suffered a few ricochets from an anti tank gun). Inside the cup was a black gum that took me some scrubbing to remove. Anything that was threaded was locked. Needed WD40 and a pair of pliers to loosen. And no, I still needed pliers to tighten it back. Finger strength didn’t move anything at all. Nozzle was jammed stuck too. WD40 again. After an hour of deep cleaning, it worked fine. Until today, even with tamiya blue cap grease or chapstick on all threads, I still need pliers to remove any part, making cleaning a chore.

You don't say....

Similar threads

- Replies

- 6

- Views

- 500

- Replies

- 9

- Views

- 2K