You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Needle Measurements

- Thread starter Johnny

- Start date

Leakyvalve

Mac-Valve Maestro!

You might be mixing up nozzle size with needle size.

******************You might be mixing up nozzle size with needle size.

Aren't needles and nozzles rated/measured the same? .2, .35, .5? A .5 needle won't fit into a .2 nozzle and a .2 needle will fit sloppily into a .5 nozzle - no?

DaveG

Airbush Analyst

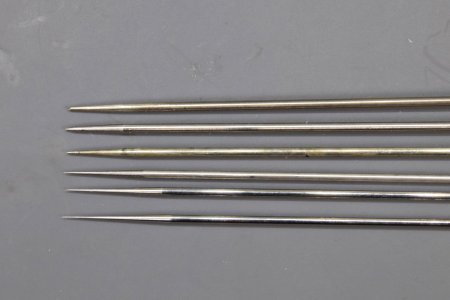

needles aren't really measured like that... Airbrushes are given a particular nozzle size, say a .2, .3, or .5 etc. Each nozzle has a needle paired with it, usually with a taper that matches an angle at the nozzle exit, which creates a seal when the needle is closed. If you were to lay the needles side by side, you would likely see a difference in the length of the taper - the longest being for the smallest nozzle, the bluntest being for the largest nozzle. This is a general overview, as there are some exceptions...

***needles aren't really measured like that... Airbrushes are given a particular nozzle size, say a .2, .3, or .5 etc. Each nozzle has a needle paired with it, usually with a taper that matches an angle at the nozzle exit, which creates a seal when the needle is closed. If you were to lay the needles side by side, you would likely see a difference in the length of the taper - the longest being for the smallest nozzle, the bluntest being for the largest nozzle. This is a general overview, as there are some exceptions...

That makes sense Dave. Thank you.

Karl Becker

Mac-Valve Maestro!

DaveG nailed it. Is there a specific reason you are asking?

********DaveG nailed it. Is there a specific reason you are asking?

I've been comparing the differences between inexpensive foreign needles and nozzles

chwilson0607

Young Tutorling

I've been wanting to know the same thing. I'd like to be able to identify what size needles I have as I have several extra that I've accumulated over the years. I've seen mentioned you can use digital calipers to measure but I'm unsure how or where on the needle to do this. ALong with that, is there a way to identify nozzle size once out of the packaging?

DaveG

Airbush Analyst

I've been wanting to know the same thing. I'd like to be able to identify what size needles I have as I have several extra that I've accumulated over the years. I've seen mentioned you can use digital calipers to measure but I'm unsure how or where on the needle to do this. ALong with that, is there a way to identify nozzle size once out of the packaging?

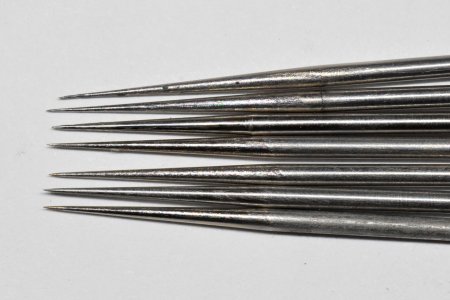

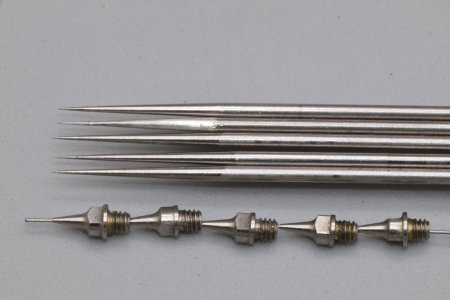

As I started in an earlier post, needles are not really measured like that. It is the nozzle that has a certain size dictated by the nozzle opening. If you have more than one needle, but are not sure of size - In general, smaller sized needles will have longer tapers, with finer points. The larger the nozzle opening, normally the shorter the needle taper, and the blunter the point. If you have at least one needle you know the size of, you can generally at least guess at the others by laying them all out and examining the taper at the front of the needle.

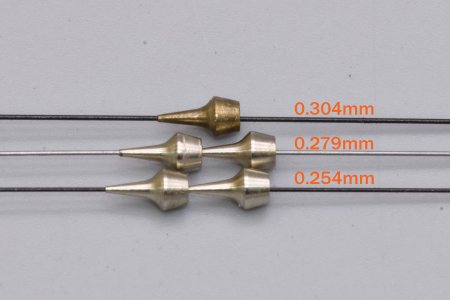

"Measuring" a needle is kind of futile, because where do you measure? There is no one location that will tell a given size - besides, this group of needles is all one part number, yet they vary quite a bit upon close inspection -

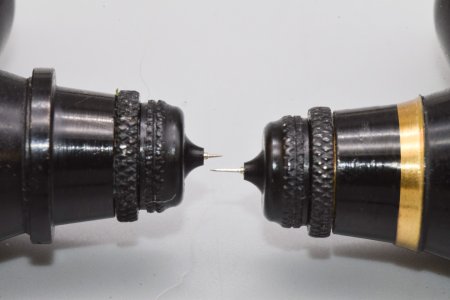

Another way to guesstimate what needle you may have, is if you know what size nozzle your airbrush currently has, you can simply slip a needle in, and compare the protrusion (the amount the needle sticks out the front) to the previous one you know. In general, a larger needle will have a shorter taper, and thus not protrude as far from any given nozzle. A medium, or .3 needle will not stick out of a .2 nozzle as much as a fine, or .2 needle will. There is a caveat of course, as both nozzles and needles in this photo are actually marked as the same size.

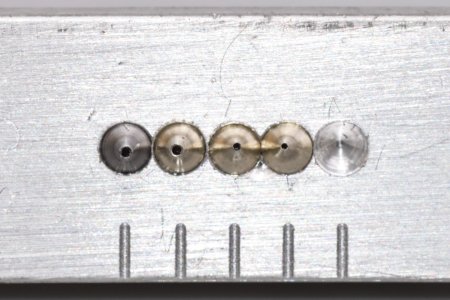

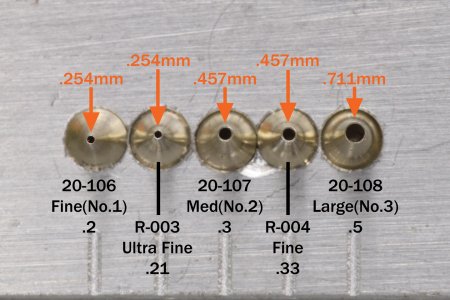

Now, about nozzles. These are the parts that are actually measured. I look at the numbers given to them more as an indicator of general size. A .2 nozzle is small, .3 medium, .5 large, etc... because when you do actually measure them, they make no sense

There is a way to actually measure them. I use precision "go or no-go" gauge pins that are accurate down to 0.0002". They are accurately sized wire pins that are inserted into a hole to determine the holes actual size. Here one advertised size of nozzle has been slipped onto pins to determine actual size. The variation between them can be seen by the fact that they fit different sized pins.

Some manufacturers tolerances are tighter than others, which can be seen when measuring -

So, using gauge pins you can measure what size nozzles actually are - Here the top numbers are actual measurements, while the bottom are part numbers and advertised size. I have always guessed at truth being that when a manufacturer specifies a size, like a .2, that that is the maximum opening size achieved by a nozzle when the needle is withdrawn fully by the trigger

So, the bottom line is - if you have one set up you know the size of, you can pretty much guess at what the others are by doing a visual comparison. Actual measuring is not always practical, or feasible.

Hope this helps...

Last edited:

chwilson0607

Young Tutorling

I have lots of photographs on another computer that I will come back in and edit this post with -

As I started in an earlier post, needles are not really measured like that. It is the nozzle that has a certain size dictated by the nozzle opening.

Never mind - switched computers and am working on editing this post - check back in a bit

Thanks DaveG. I found the other thread where you explained this and it makes sense. I just wonder why needle manufacturers don't make some sort of method for IDing needles. Yes I should have been better at keeping them "tagged" and together with matching nozzle.

DaveG

Airbush Analyst

Thanks DaveG. I found the other thread where you explained this and it makes sense. I just wonder why needle manufacturers don't make some sort of method for IDing needles. Yes I should have been better at keeping them "tagged" and together with matching nozzle.

If you have a brush you know the size of the needle on, mark the back of the needle in a way you will recognize it. Before I remove a .2 needle from a brush, I will cut two hashes in the back with a dremel using a cutting wheel. That way I will always know that needle is a .2... Between brands, I wrap a piece of tape around, and simply write the makes name if they are to be stored...

chwilson0607

Young Tutorling

If you have a brush you know the size of the needle on, mark the back of the needle in a way you will recognize it. Before I remove a .2 needle from a brush, I will cut two hashes in the back with a dremel using a cutting wheel. That way I will always know that needle is a .2... Between brands, I wrap a piece of tape around, and simply write the makes name if they are to be stored...

Great idea. I have a few that have never been changed out to confirm the needle size. I just happen to have a Dremel too.

Thanks Dave

Similar threads

- Replies

- 31

- Views

- 1K