J

John V

Guest

Hi all

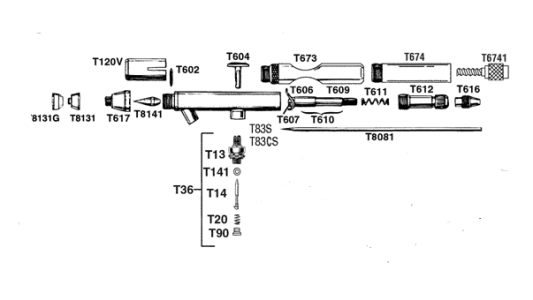

My TC Omni 5000 AB has an air leak when I depress the finger rocker. The leak goes out around the rocker trigger. I can hear it and if I put water on it the trigger bubbles, But no air is leaking through the nozzle.

The air leak only happens when the trigger is pressed for air.

The AB is working but I do not think air is supposed to work this way.

Thank you for your help.

My TC Omni 5000 AB has an air leak when I depress the finger rocker. The leak goes out around the rocker trigger. I can hear it and if I put water on it the trigger bubbles, But no air is leaking through the nozzle.

The air leak only happens when the trigger is pressed for air.

The AB is working but I do not think air is supposed to work this way.

Thank you for your help.