palk

Needle-chuck Ninja

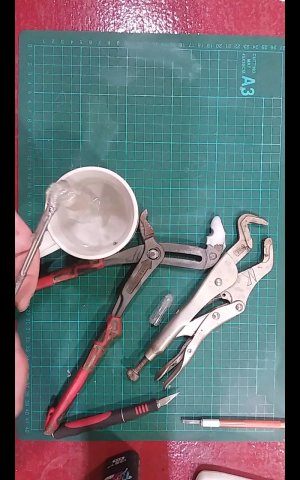

I made a set of specific soft jaw pliers for airbrushes the crown cap, air cap and air valve housing.

I used a low melt plastic Polycarpalactone(PCL) or it's trade name on Bay poly morph.

Bay poly morph.

It melts at +60 degrees celsius in hot water and turns into a clear toffee consistency. When it touches a heat conducive surface at below 10Deg C the PCL solidifies a thin skin rapidly.

I will be making a couple of mk2 versions when I find a set dual opening size pliers from a Toyota cars tool kit

Here is a link to a +7 minute youtube clip of "what i did" more than "how too" video below

I used a low melt plastic Polycarpalactone(PCL) or it's trade name on

It melts at +60 degrees celsius in hot water and turns into a clear toffee consistency. When it touches a heat conducive surface at below 10Deg C the PCL solidifies a thin skin rapidly.

I will be making a couple of mk2 versions when I find a set dual opening size pliers from a Toyota cars tool kit

Here is a link to a +7 minute youtube clip of "what i did" more than "how too" video below

Attachments

-

Screenshot_20230730-030001_Video Player.jpg597 KB · Views: 7

Screenshot_20230730-030001_Video Player.jpg597 KB · Views: 7 -

20230730_012420.jpg159 KB · Views: 6

20230730_012420.jpg159 KB · Views: 6 -

Screenshot_20230730-015719_Video Player.jpg683.5 KB · Views: 4

Screenshot_20230730-015719_Video Player.jpg683.5 KB · Views: 4 -

Screenshot_20230730-021533_Video Player.jpg648.8 KB · Views: 4

Screenshot_20230730-021533_Video Player.jpg648.8 KB · Views: 4 -

Screenshot_20230730-021701_Video Player.jpg635.1 KB · Views: 7

Screenshot_20230730-021701_Video Player.jpg635.1 KB · Views: 7 -

Screenshot_20230730-011526_Video Player.jpg574.2 KB · Views: 7

Screenshot_20230730-011526_Video Player.jpg574.2 KB · Views: 7